Difference between revisions of "Msc3workshop2G3:P2"

| (7 intermediate revisions by one user not shown) | |||

| Line 1: | Line 1: | ||

__NOTOC__ __NOTITLE__ | __NOTOC__ __NOTITLE__ | ||

| − | <div>[[File: | + | <div>[[File:Informed_Porosity_Wiki_Illustrator-01.png | 850x450px]]</div> |

| − | '''Pavilion | + | '''Pavilion Shelter''' |

| + | |||

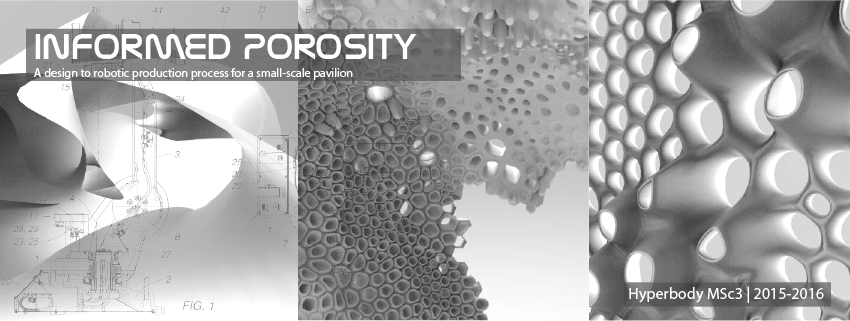

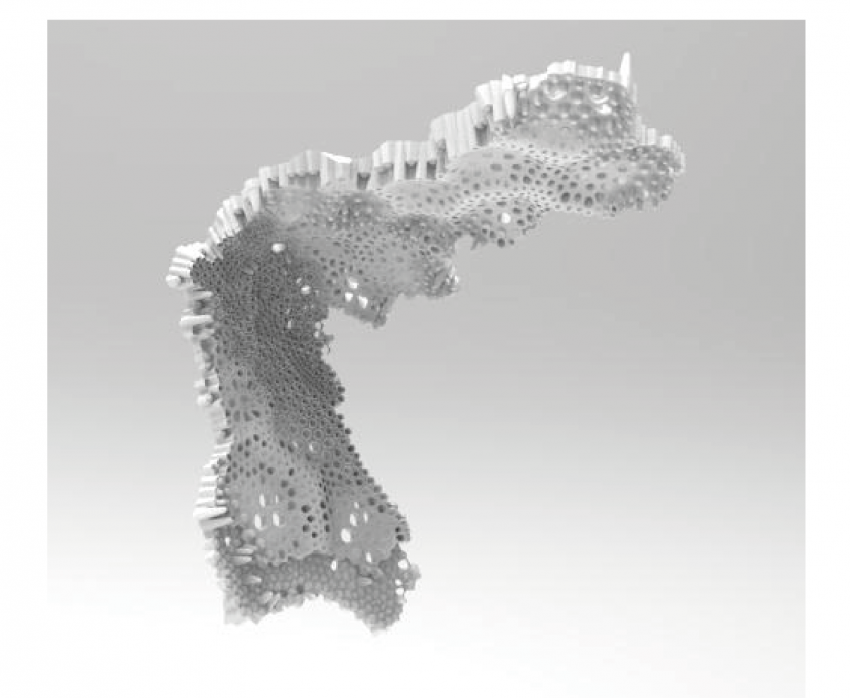

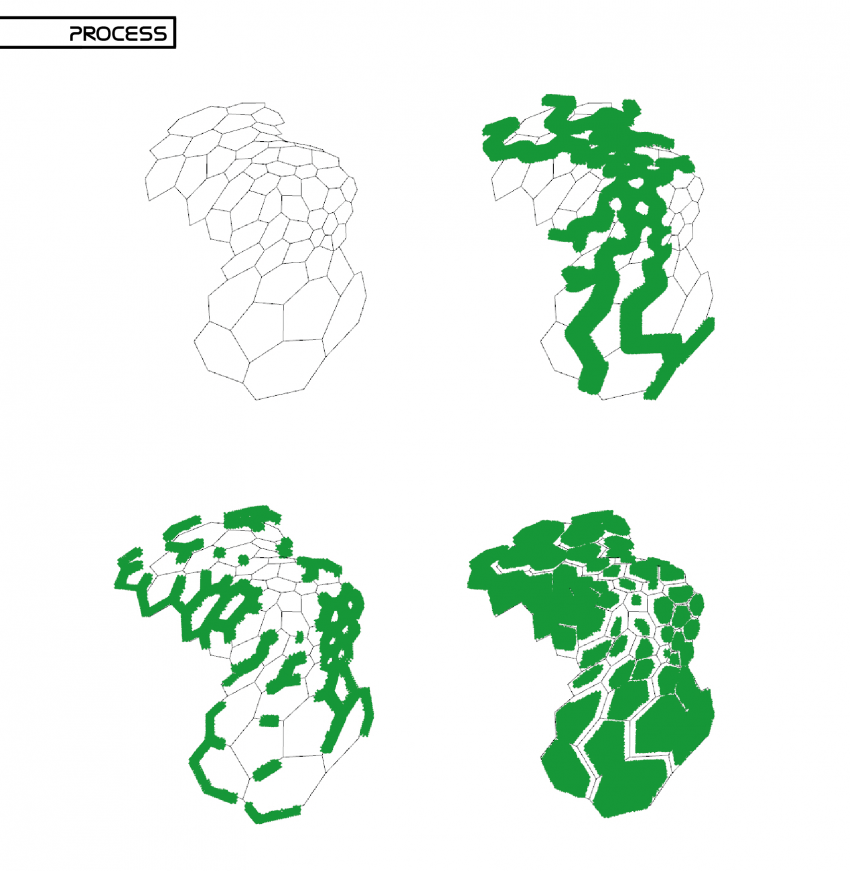

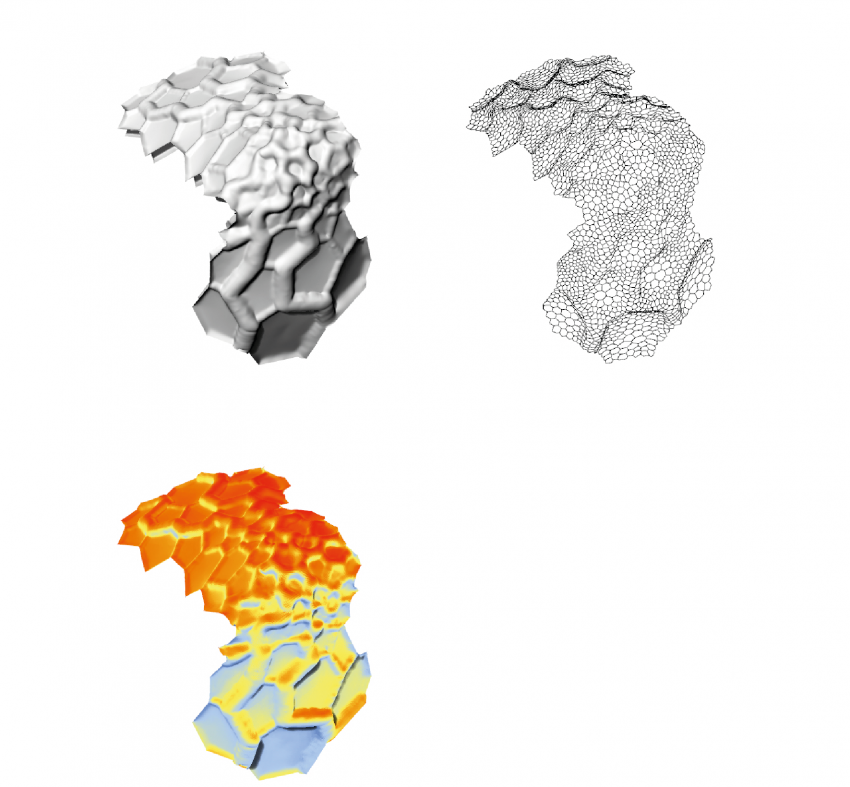

| + | ''This workshop aims to explore design to robotic production techniques, using a drilling head mounted on a six-axis industrial robotic arm and controlled with Grasshopper, in order to fabricate a 1:1 scaled section of a small-scaled pavilion located in Rotterdam - Leuvehoofd, situated near the Erasmus Bridge. Focussing on the theme '''Porosity''', the intend was to inform the structure with as many local and global parameters as possible, exploring how these will influence the macro, meso and micro scales of the project and how these eventually will relate to each other. The final result of the workshop are three components milled out of EPS-250 foam, together forming a roof to wall section. The prototype functions as both a sketch and proof of concept of a parametric design system that is to be further developed in order to design other buildings (our graduations projects) with it. For us, the process we developed during this workshop will function as a blueprint for how we are to approach our graduation projects. | ||

| + | '' | ||

| + | |||

| + | '''360 degrees render of the first component:''' http://arwinhidding.nl/prototype%20versie%202_VR.13.html | ||

| − | |||

| − | |||

| − | |||

'''Design Team: Ralph Cloot (4329821) | Arwin Hidding (4301811)''' | '''Design Team: Ralph Cloot (4329821) | Arwin Hidding (4301811)''' | ||

| − | '''Tutors: Henriette Bier | + | '''Tutors: Henriette Bier | Sina Mostafavi''' |

<div style="height:30px; width: 850px; margin:0px; padding: 0px; padding-top: 20px; border: 0px;"> | <div style="height:30px; width: 850px; margin:0px; padding: 0px; padding-top: 20px; border: 0px;"> | ||

Latest revision as of 11:23, 6 April 2016

Pavilion Shelter

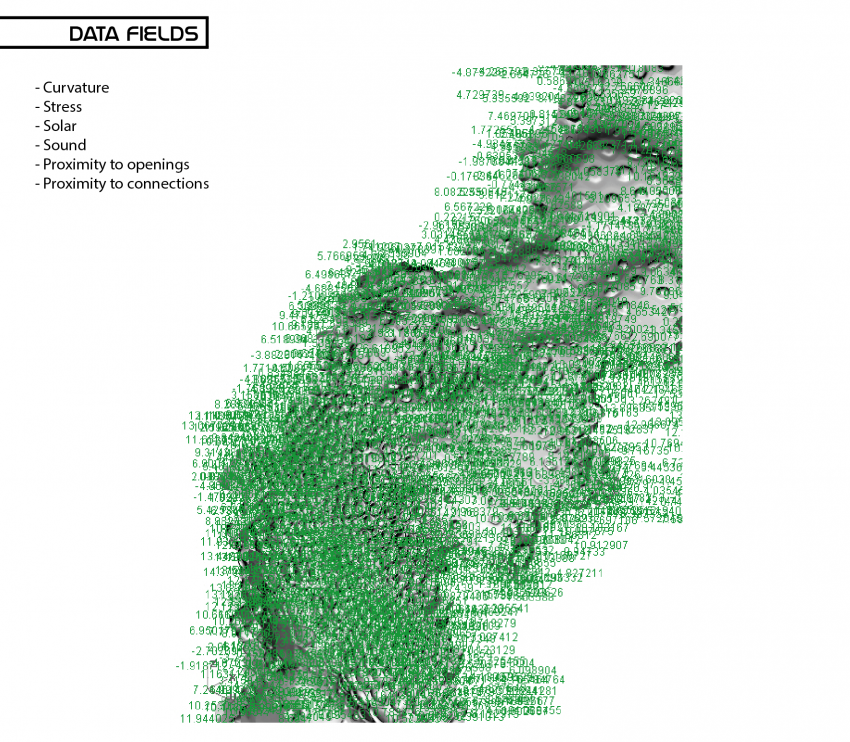

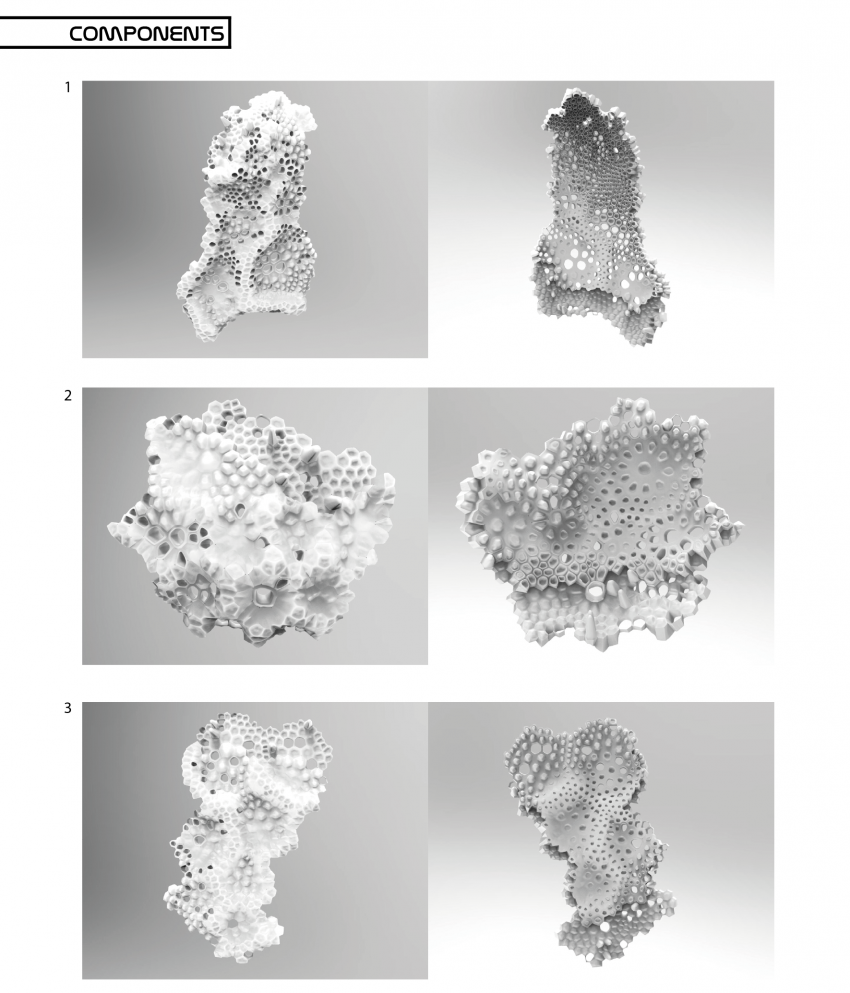

This workshop aims to explore design to robotic production techniques, using a drilling head mounted on a six-axis industrial robotic arm and controlled with Grasshopper, in order to fabricate a 1:1 scaled section of a small-scaled pavilion located in Rotterdam - Leuvehoofd, situated near the Erasmus Bridge. Focussing on the theme Porosity, the intend was to inform the structure with as many local and global parameters as possible, exploring how these will influence the macro, meso and micro scales of the project and how these eventually will relate to each other. The final result of the workshop are three components milled out of EPS-250 foam, together forming a roof to wall section. The prototype functions as both a sketch and proof of concept of a parametric design system that is to be further developed in order to design other buildings (our graduations projects) with it. For us, the process we developed during this workshop will function as a blueprint for how we are to approach our graduation projects.

360 degrees render of the first component: http://arwinhidding.nl/prototype%20versie%202_VR.13.html

Design Team: Ralph Cloot (4329821) | Arwin Hidding (4301811)

Tutors: Henriette Bier | Sina Mostafavi